Hot Rolling

Elmet Technologies provides its customers with advanced hot rolling services for refractory metals and other high-performance materials. We leverage our decades of expertise in powder metallurgy, thermal management, and material processing to deliver superior results for your applications. Our team of highly skilled metal rolling technicians bring decades of experience to every project. We ensure the highest standards of quality and performance. We achieve optimal surface quality and performance properties by tightly controlling the rolling environment, parameters, and a meticulous process for ensuring material quality.

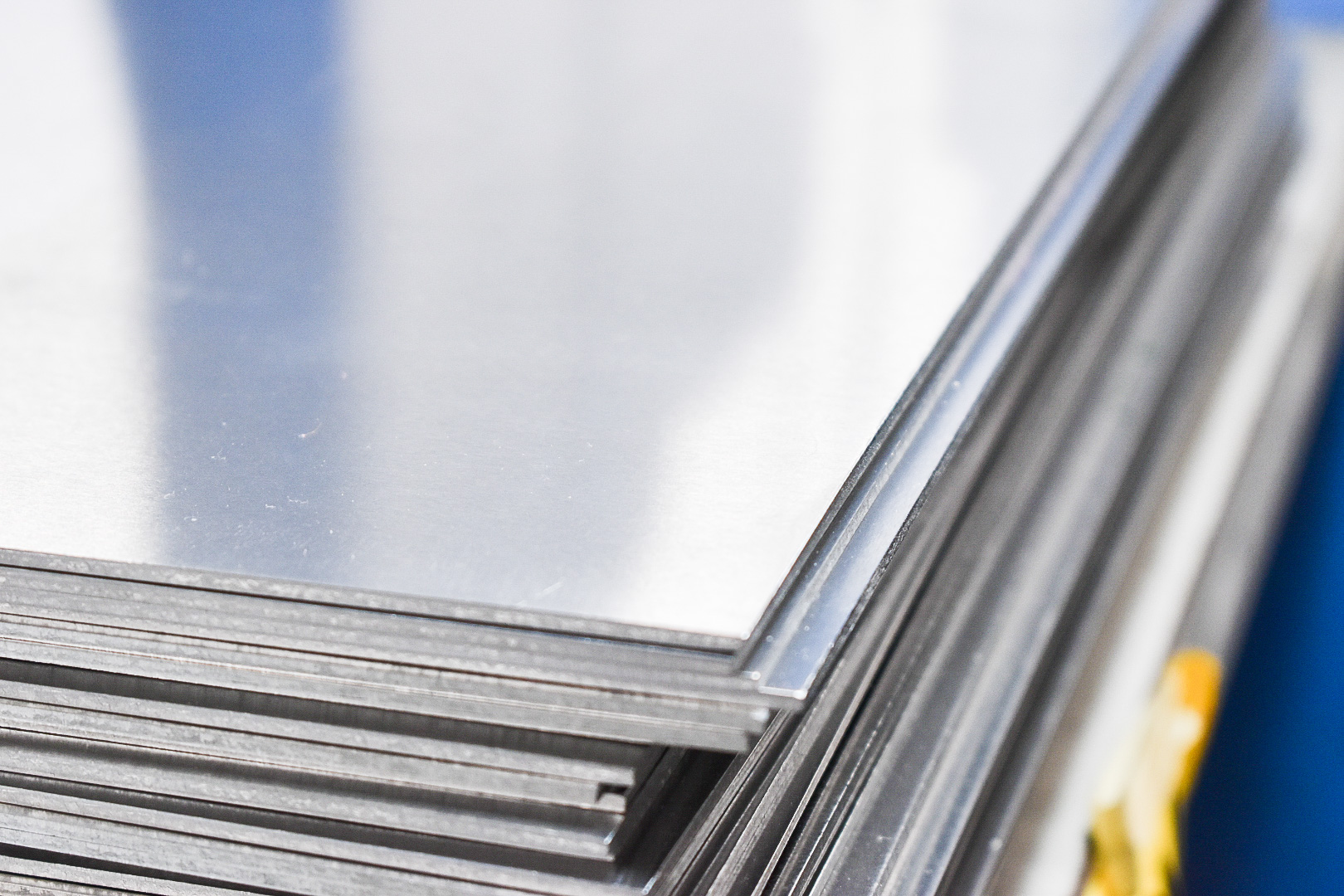

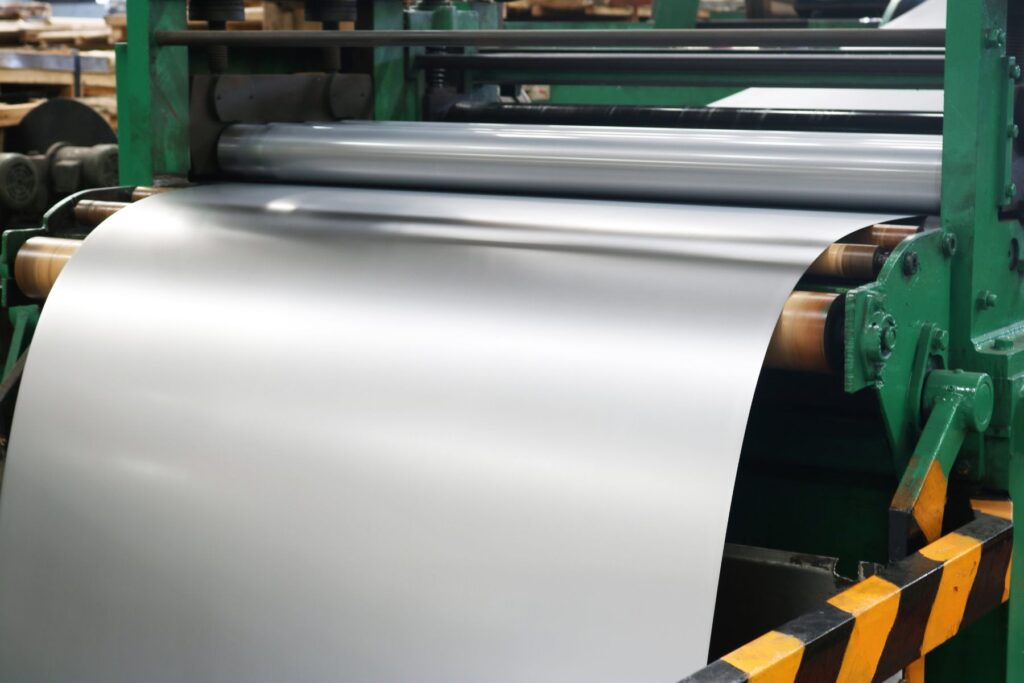

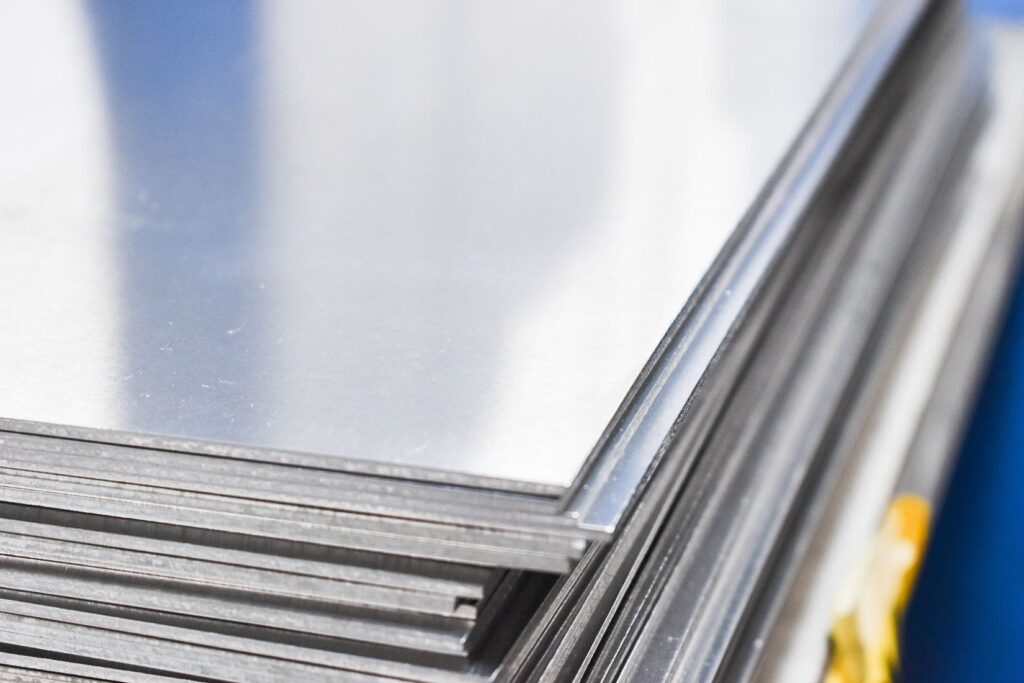

With 9 rolling mills across our facilities, Elmet Technologies leverages several types of rolling methods to transform materials into flat metal products. Our hot rolling process considers critical material properties like thermal stability and durability, while achieving precise thickness and dimensions. Through multiple annealing and rolling cycles, we deliver high-quality results on a consistent basis. Elmet Technologies is an ideal partner for your hot rolling requirements.

Advanced Hot Rolling Services

Hot rolling is a specialized metalworking process that takes place above the material’s recrystallization temperature. This method allows for the deformation of the metal grains to a point where they recrystallize, maintaining an equiaxed microstructure and preventing work hardening. Typically, this process begins with large pieces of metal, including ingots, slabs, blooms, and billets, which are transformed into thinner sheets or simple cross-sections.

At Elmet Technologies, our hot rolling services enable us to treat materials and roll products to meet precise customer specifications, including desired thickness, length, and surface finish, while also offering the ability to tailor other material properties.

The Benefits of Rolling High-Performance Metals

Improved Workability

Hot-rolled metal is significantly more pliable, making it easier to form and shape due to the extremely high temperatures used in the rolling process.

Exceptional Performance

Hot rolling refines grain structure, removes defects, and enhances ductility, strength, and toughness, making it ideal for mechanical applications.

Economical Costs

Hot-rolling uses less energy due to lower resistance at high temperatures, making it more cost-effective. Thus, favorable economic outcomes are a result.

Minimized Internal Stress

The cooling process during production reduces internal stresses within the material, enhancing its stability, uniformity, and overall durability.

Hot Rolling of Refractory Metal flat products

As a leading global manufacturer of molybdenum and tungsten flat products, Elmet Technologies leverages 9 hot rolling mills and advanced manufacturing techniques to transform refractory metal materials into flat products, fabricated exactly to customer specification. Starting with metal powder that is pressed into ingots, sintered, and meticulously rolled, we craft molybdenum, tungsten, niobium, and other high-performance materials to meet your unique requirements.

Elmet Technologies offers cut-to-size or rolled options according to customer-specified thickness, length, surface finish, and other material properties. Our three fully-integrated U.S. facilities manufacture all products to meet or exceed the highest standards in the industry. Customers can choose stress-relieved or recrystallized products in various finishes and sizes. We can enhance material performance properties to align products with specific application needs.

Common Materials and refractory metals

Elmet Technologies commonly manufactures flat products from refractory metals and other high-performance materials. Our materials involved in rolling and flat products include:

- Molybdenum

- Lanthanated Molybdenum

- TZM

- MP35N

- Tungsten

- CuMoCu

- NiMoNi

- High-Performance Alloys

Rolling Services for Customer Materials

Elmet Technologies utilizes its expertise in hot rolling refractory metals and high-performance materials to offer metal processing services for customer-specified materials.

We regularly process unique metals and specialty alloys, and work with our customers as a partner to deliver metal rolling services to make your product a success.

Our highly qualified team of process engineers, rolling technicians, and material scientists know the right rolling conditions and parameters to process metals into their final form.

Start a discussion with our team of experts today to learn more about our rolling services.