Cold Rolling

Elmet Technologies provides industry-leading cold rolling services for a wide range of high-performance materials and refractory metals. We deliver exceptional surface quality and precise material specifications to meet the most demanding industry requirements. With decades of expertise, our skilled process engineers use advanced techniques and state-of-the-art equipment to optimize rolling conditions, producing high-performance metal solutions for a variety of applications.

We have dedicated team of rolling technicians and material experts, offering a meticulous attention to detail in the rolling process. This ensures proper material pre-processing, which delivers consistent and reliable results for every project. Through a steadfast commitment to quality and innovation, Elmet Technologies has established itself as a leader in cold rolling services. We support industries such as aerospace, defense, medical, and energy with quality flat-rolled metal products.

Specialized Metal Rolling Services

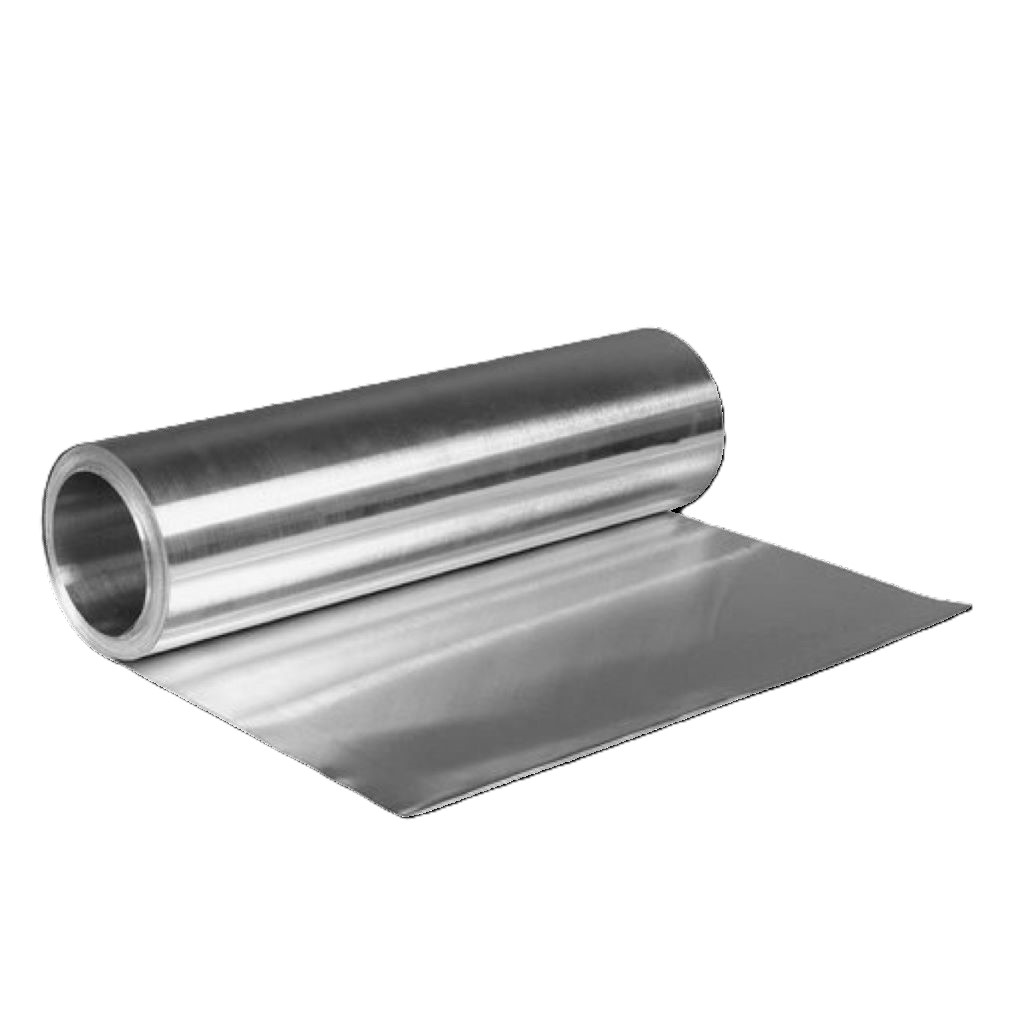

Elmet Technologies offers specialized cold rolling services that roll thick metal forms into thinner flat products, without compromising the integral properties of the materials. At times, this process has the ability to even increase the strength of the metal by as much as 20%. This is completed via strain hardening through the cold rolling process, conducted below the metal recrystallization temperature, typically at room temperature. Additionally, this process significantly improves the surface finish while maintaining precision with tighter tolerances.

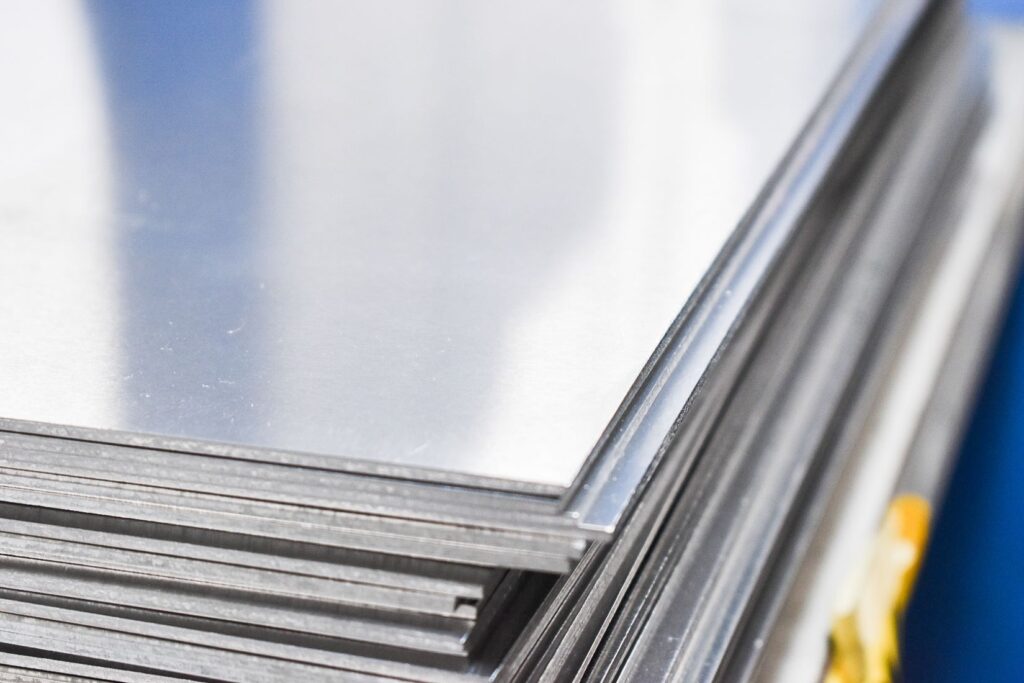

We provide rolling services and a variety of flat products, such as sheet, plate, foil, and more. These are generally smaller yet stronger than their hot-rolled counterparts, necessitating the use of advanced four-high or cluster mills for processing. While cold rolling is less effective than hot rolling in reducing thickness in a single pass, our capabilities extend to cutting, sizing, and rolling products to meet specific customer requirements. We have the ability to customize thickness, length, and surface finish, among several other material properties.

Cold Rolling Services For HIgh-Performance Metals

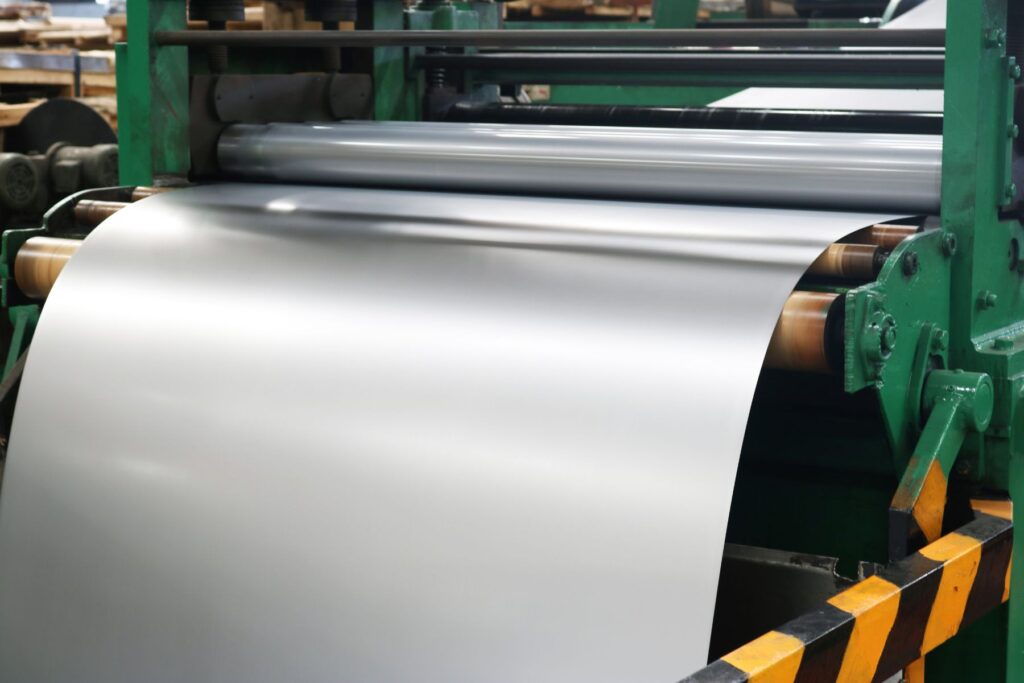

As a leading global manufacturer of refractory metal flat products, Elmet Technologies leverages its advanced manufacturing techniques and processes to provide cold rolling services for a wide variety of high-performance metals. Starting with metal powder that is pressed into ingots and sintered, we employ precise rolling processes to roll molybdenum, tungsten, niobium, and high-performance metal alloys into flat metal parts and shapes that meet customer requirements.

Our cold rolling capabilities allow for exceptional control over material thickness, surface finish, and other properties, ensuring products meet exact customer specifications. Our manufacturing facilities are fully-integrated with ISO 9001 and AS9100 certifications. With a total of 9 large rolling mills at our facilities, customers can select from a range of standard and custom products, with various finishes and sizes. We can also optimize material to the specific application.

The Benefits of Cold Rolling High-Performance Metals

Versatility

Cold-rolled metal can be produced in various forms, such as full-hard, quarter-hard, skin-rolled, and half-hard, depending on the desired properties and available resources.

Precision

Materials that are cold rolled offer precise dimensions, tight tolerances, and a smooth surface finish ideal for high-precision component manufacturing.

Surface Finish

Cold rolling mills produce exceptionally high-quality materials with a smoother, cleaner, and more polished surface that better resists corrosion, rust, and wear.

Strength

Cold-rolled metals have the potential to be 20% stronger than hot-rolled metal, making it ideal for high-stress applications due to the hardening process at low temperatures.

Refractory Metals and common Materials

Elmet Technologies transforms a wide range of high-performance metals, alloys, and materials into flat products through its rolling techniques. Common materials for rolling flat products include:

Cold Rolling Customer Materials

Elmet Technologies offers cold rolling services for a diverse range of applications and customers. We utilize our large capacity with several rolling mills across our U.S. facilities to assist customers with thermal management solutions and flat products that exceed their expectations. Capabilities in cold rolling customer materials include:

- Ability to process a wide range of high-performance materials and refractory metals.

- Prototyping or high volume manufacturing of flat products: sheet, plate, foil, and more.

- Specialty rolling of unique alloys with developmental programs for non-common alloys.