Extrusion

Elmet Technologies provides industry-leading extrusion services for a wide range of refractory metals and high-performance metals. Through a fully-integrated manufacturing process, we regularly procure the material, manufacture the billet, extrude it, and finish it to precise customer specifications with fast delivery times. We provide a wide range of finishing processes to suit nearly any application, including heat treatment, cleaning, straightening, machining, cutting, and more.

We assist our customers by solving their most demanding material processing and fabrication challenges. By combining state-of-the-art extrusion technology with an extensive knowledge in the processing and metallurgy of a wide spectrum of metals, we are unique in our ability to extrude nearly any metal in nearly any size range. Our highly skilled team of engineers and metallurgists can assist with the processing of materials to meet your exact performance requirements.

Extrusion for High-Performance MEtals

Elmet Technologies’ Coldwater, Michigan, facility is home to advanced extrusion equipment that combines cutting-edge computerized controls with ultra-precise hydraulics. Our world-class 5,000 metric ton (5,500 ton) extrusion press achieves processing speeds that range from 0.01″ to 12″ per second.

Advanced processing equipment allows us to manufacture extrusions with diameters ranging from 152 to 457 mm (6 to 18 inches). By preheating billets up to 1925°C (3500°F) via gas-fired or inert atmosphere induction furnaces and meticulous control of ram speed, we offer unique capabilities in metal processing. These capabilities allow us to deliver high-performance solutions for precise customer requirements.

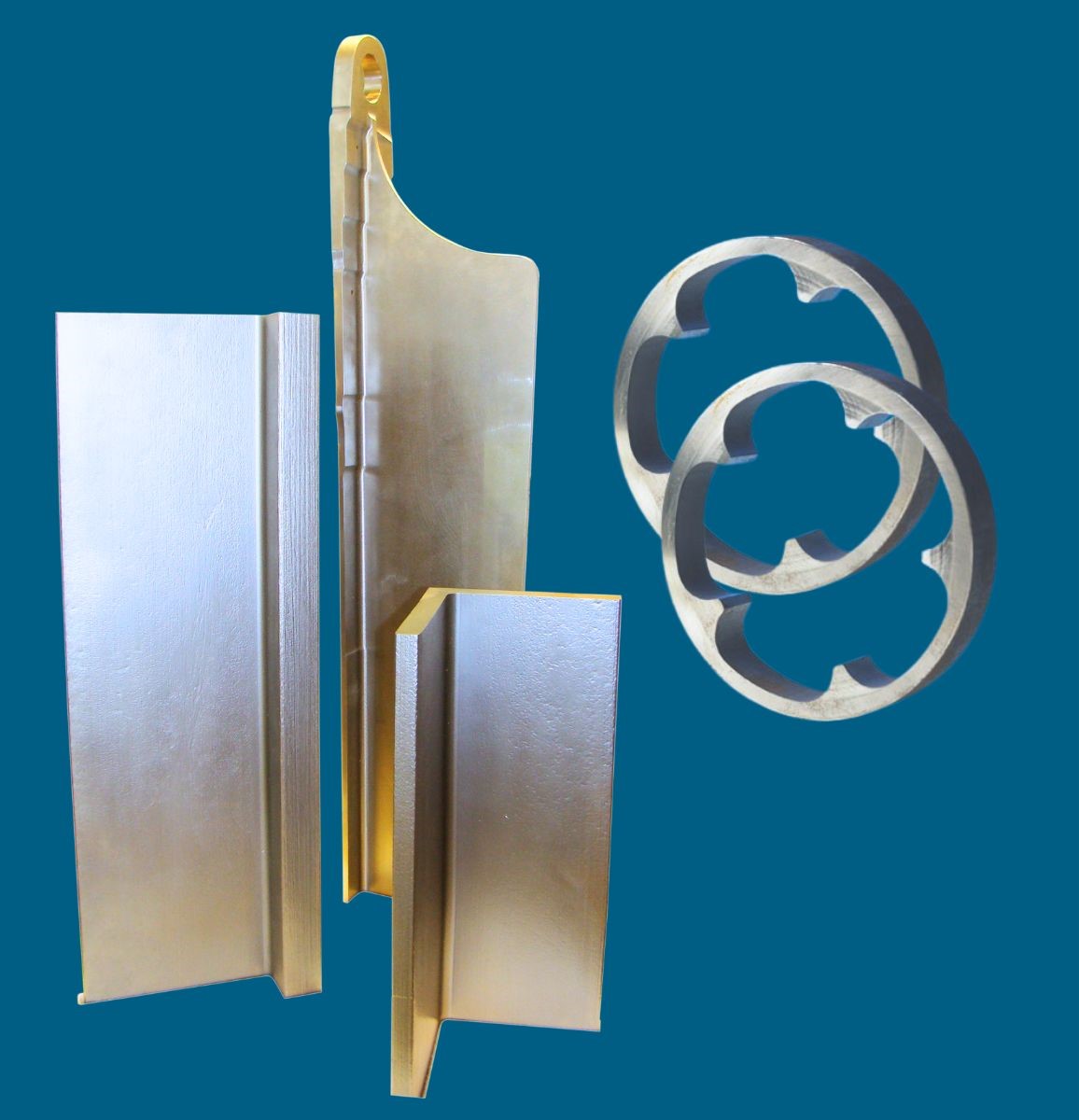

Our Capabilities For Extruded Shapes

We have expertise in manufacturing high-quality extruded shapes tailored to meet the requirements of demanding applications. Our strengths include manufacturing extruded shapes such as:

- Back Extrusions

- Flats

- Piercing Solutions

- Upsets / Compaction

- Hollows and Tubes

- Extruded Cans

- Rounds

- Custom Shapes

High-Performance Extrusion and processing Equipment

In addition to our state-of-the-art extrusion press and processing equipment, we operate two high-capacity billet heating furnaces, capable of achieving temperatures ranging from 1000°F to 2400°F. These furnaces accommodate both oxidizing and reducing atmospheres. They are also equipped with rapid lateral transfer systems to ensure superior processing efficiency.

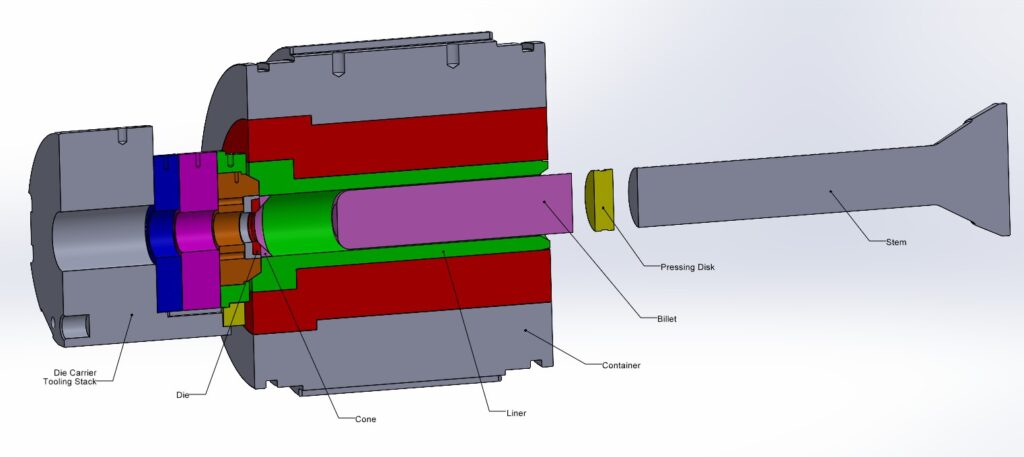

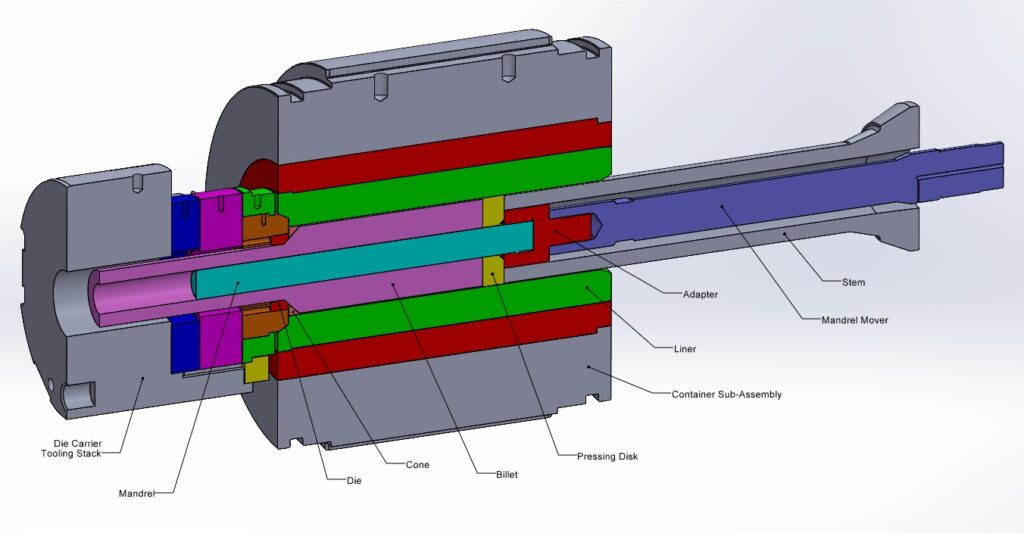

FORWARD EXTRUSION

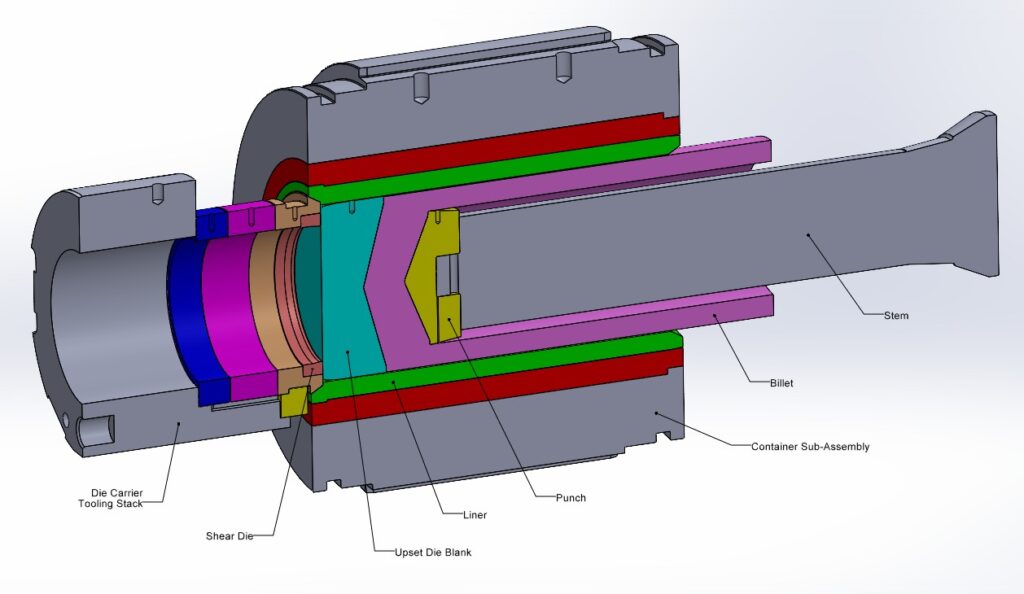

BACK EXTRUSION

DIRECT FORWARD EXTRUSION

Additionally, a separate pusher block heating furnace is incorporated for enhanced performance. A powerful overhead crane, with a 15-ton capacity, seamlessly operates along the entire length of the facility, facilitating effortless product handling.

Extrusion Equipment capabilities

- Billet Temperature

- 260-1350°C (500–2400°F) gas fired

- 200-1370°C (400-2500°F) induction inert atmosphere

- Input Billet Diameter

- 152-457 mm (6-18 in) diameters

- Extrusion Ram Speed

- Widest range available

- 127–203 mm/sec (0.01–12.0 in/sec)

- Force

- 5,000 Metric Tons (5,500 tons)

- Water Pressure

- 4250 lb/sq inch (psi)

Elmet Technologies Extrusion Process At-A-Glance

Machined Billets

Preheat*

Load Press

Extrude Material

Inspect

Package & Ship

*After preheating, depending on the material being used, we can also do induction heat before then loading into the press.

State-of-the-Art Extrusion Technology

Our extrusion expertise comprises specialty metals and alloy based systems including titanium, molybdenum, tantalum, niobium and other high-performance metals for large extrusion applications.