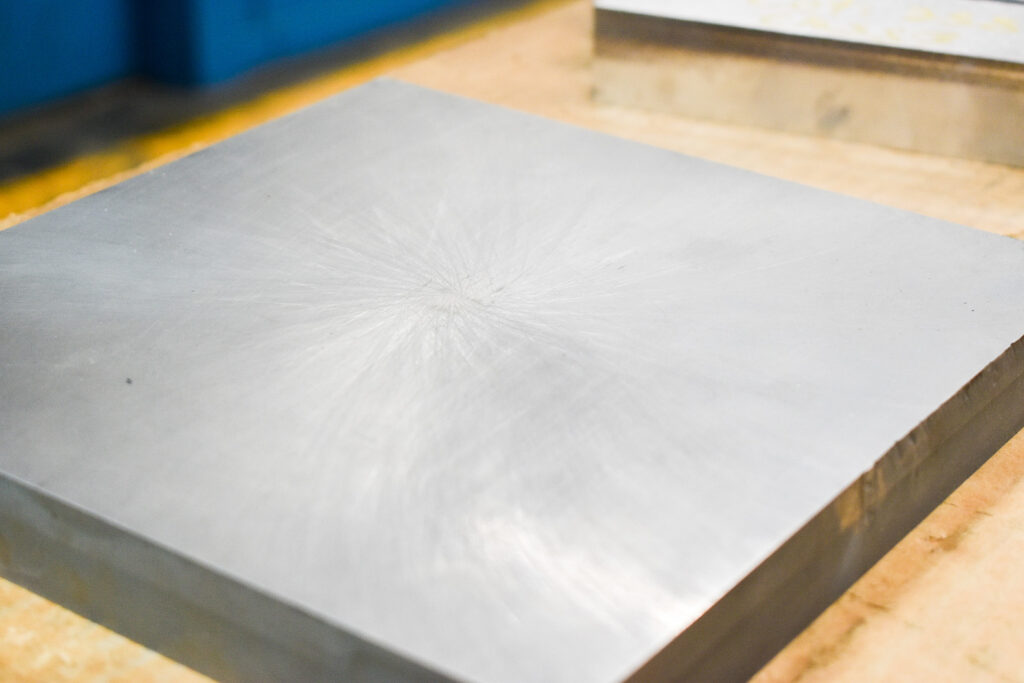

MP35N Plate

Elmet Technologies is a global leader in manufacturing high-performance MP35N plate for a wide range of demanding applications. This ultra-high-strength metal alloy is engineered for exceptional durability, toughness, and superior corrosion resistance. We produce this alloy in various flat product forms to meet the stringent requirements of the most demanding industries, from aerospace and defense, to medical and energy. Our commitment to quality ensures that every product delivers unmatched performance in critical applications. Our flat-rolled MP35N products and materials are manufactured to exact customer specifications.

MP35N is a unique multiphase alloy, typically consisting of 35% nickel, 35% cobalt, 20% chromium, and 10% molybdenum. This precise composition, achieved through advanced vacuum induction melting and vacuum arc re-melting processes, gives our plate its remarkable properties. It is an ideal material for applications where high strength, ductility, and corrosion resistance are essential. It also offers reliability for environments in which temperature may be a critical factor.

High-Performance MP35n Plate

We engineer our MP35N plate for exceptional performance, even under extreme stress. By utilizing advanced rolling processes, we significantly enhance the strength of the alloy and material, while also maintaining outstanding ductility.

- Ultra-High Tensile Strength: Achieves strength levels of 260 to 300 ksi (1790 to 2070 MPa).

- Exceptional Toughness: Maintains excellent ductility, with a reduction in area greater than 40%.

- Reliable Temperature Performance: Operates effectively from cryogenic conditions up to 600°F (316°C) without embrittlement or loss of performance.

Advanced mp35n Alloy DEVELOPMENT

Elmet Technologies utilizes advanced production methods to manufacture MP35N plate with unparalleled consistency and quality. Our vertically integrated supply chain gives us complete control over the entire process, from raw material to finished product.

- Alloy Composition: 35% Nickel, 35% Cobalt, 20% Chromium, and 10% Molybdenum.

- Enhanced by Work Hardening: Strength is developed through mechanical working and can be further increased with an aging heat treatment.

- Production Process: Produced via vacuum induction melting (VIM) and consumable vacuum arc re-melting (VAR).

MP35N: Common Applications

Elmet Technologies MP35N plate offers and exceptional blend of ultra-high strength, durability, and corrosion resistance, making it an ideal material for a wide range of industries.

- Aerospace & Defense: Used for critical components on aircraft equipment.

- Oil & Gas Industry: Ideal for equipment and parts used in harsh chemical and marine environments.

- Medical Devices: Ideal for components in medical applications that require biocompatibility and strength.

- High-Tech Research: Used in high-pulse magnet research and other advanced scientific projects.

Your Partner for high-performance MP35N Plate

Elmet Technologies delivers high-performance MP35N plate products for applications that require the highest levels of performance and reliability. As a fully integrated, US-owned and operated manufacturer, our metallurgical expertise ensures exceptional quality. Our dedicated team of engineers work closely with customers to develop tailored solutions that meet precise specifications. Contact us today to learn about our commitment to product quality and dedicated customer service.