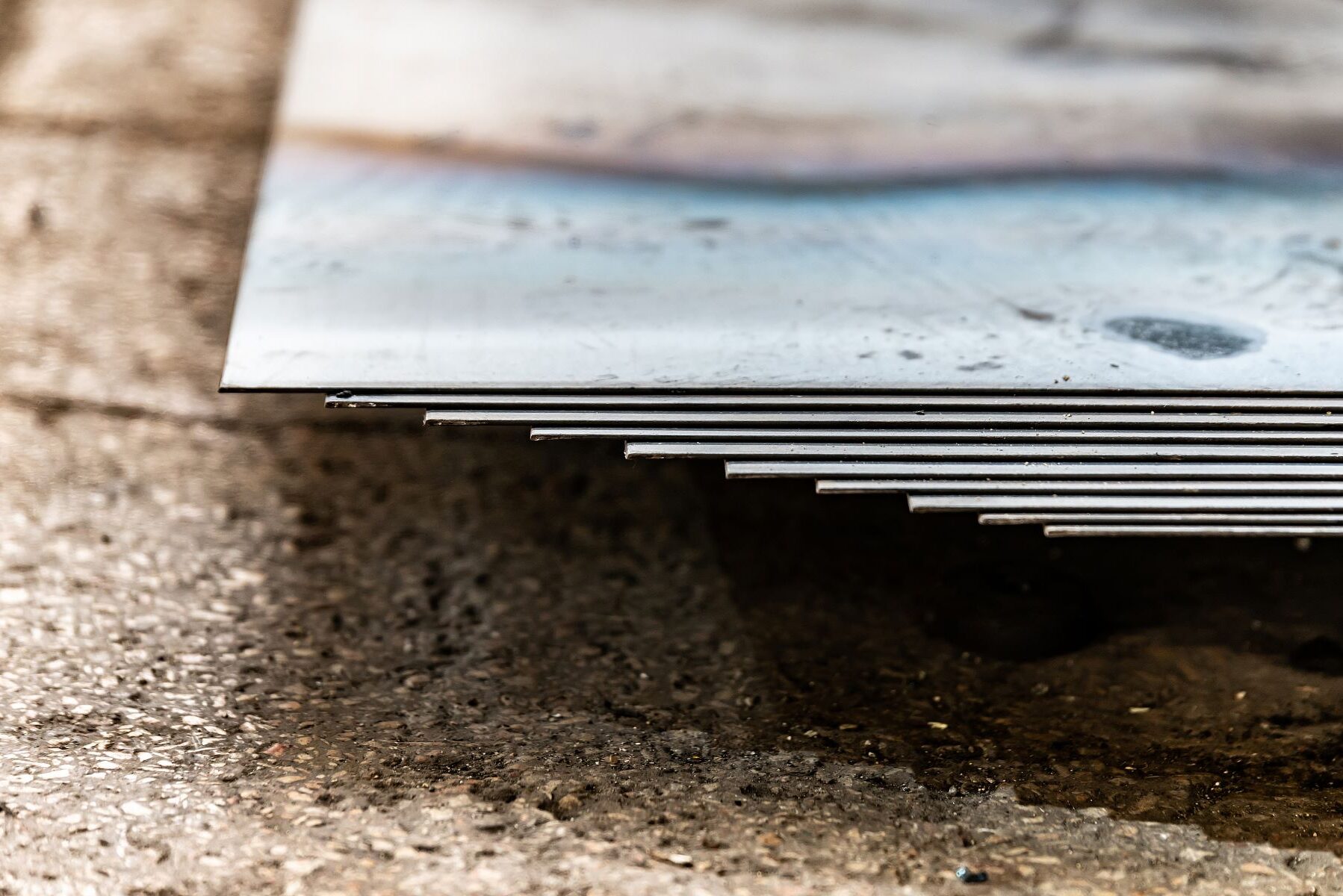

MP35N Sheet

Elmet Technologies manufactures high-performance MP35N sheet, with unique capabilities in fabricating each product to exact specification. MP35N is an advanced alloy that delivers exceptional strength, toughness, and ductility, ensuring outstanding performance even in the most extreme conditions. Produced for performance and reliability, our MP35N sheet product quality often meets or exceeds the highest standards of aerospace, defense, and scientific applications.

MP35N has a composition often consisting of 35% nickel, 35% cobalt, 20% chromium, and 10% molybdenum. It delivers exceptional strength, corrosion resistance, and reliability, even in the most demanding environments. Produced through sophisticated vacuum melting techniques, our MP35N sheet offers exceptional corrosion resistance and can be used from cryogenic temperatures to 600°F, without compromising its mechanical integrity. This makes it an ideal choice for critical components where reliability is essential. Discuss your requirements for MP35N materials, products, and solutions with Elmet Technologies dedicated team today.

High-Performance MP35N Sheet

Our MP35N sheet delivers exceptional mechanical properties, making it ideal for a wide range of high-stress applications that demand superior durability and a high modulus of elasticity. Our precision cold rolling and optional aging heat treatments enable the material to achieve ultra-high tensile strengths of 260 to 300 ksi (1790-2070 MPa). Engineered for reliable performance in a wide range of temperatures, from cryogenic lows to highs of 600°F (316°C), MP35N provides consistent and durable strength in even the most extreme environments. With Elmet Technologies expertise in alloys, each sheet is guaranteed to meet the highest standards of quality and performance.

MP35N For Demanding Applications

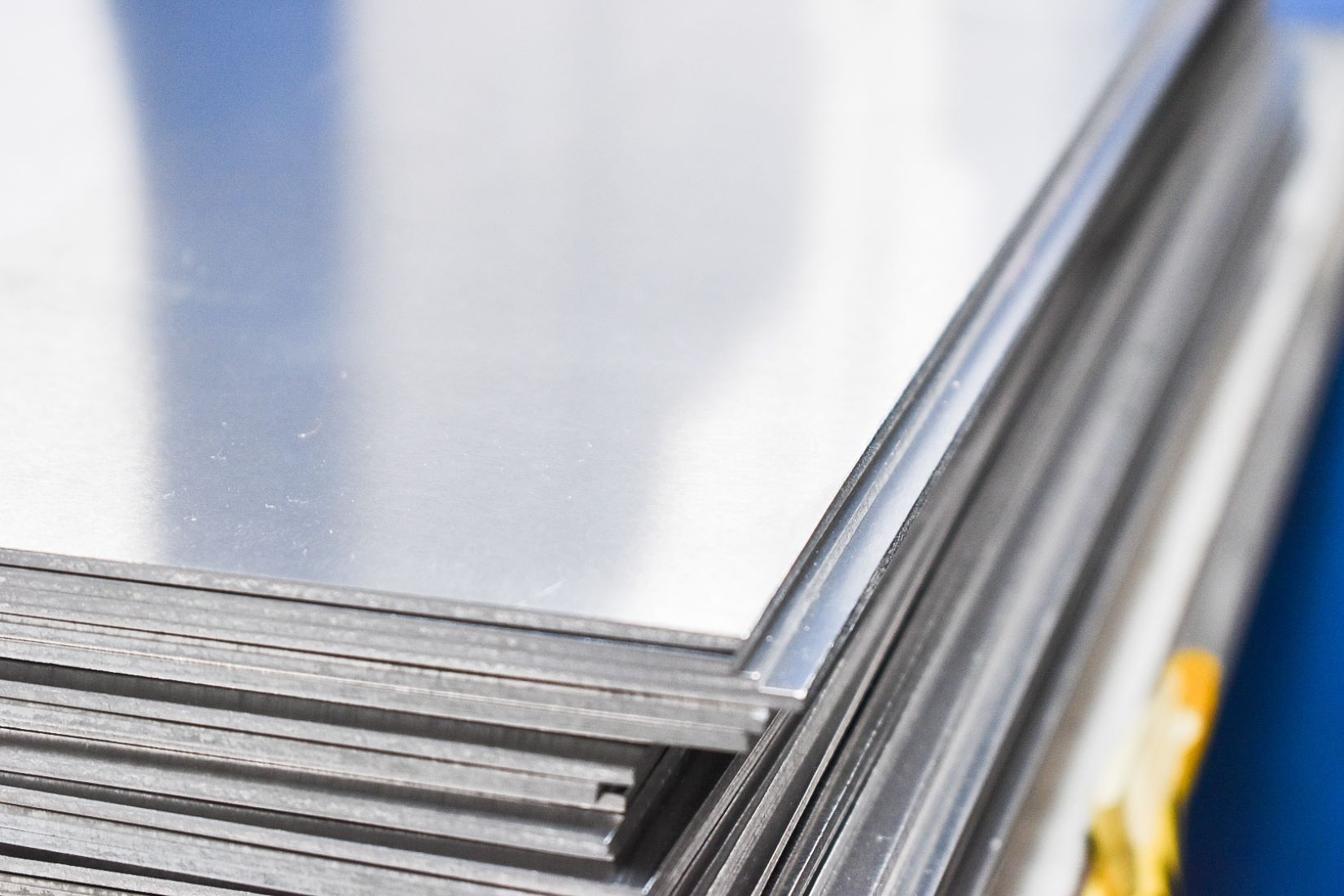

The unique properties of MP35N sheet make it an excellent material for demanding applications markets. Our flat-rolled products ensure optimized performance.

- Medical: Our sheet products are utilized in medical device applications.

- Aerospace & Defense: Ideal for various aerospace and defense components.

- Energy & Marine: Trusted for critical components and heavy-duty equipment in demanding environments.

The combination of its high temperature stability, strength, and corrosion resistance makes MP35N sheet an ideal material for demanding environments with unique challenges.

Materials for Strength and Stability

Our MP35N sheet combines exceptional corrosion resistance with high strength, making it the ideal choice for challenging environments. This specialized composition can often effectively prevent pitting, grain boundary attack, stress corrosion cracking, and hydrogen embrittlement. With superior tensile strength and a refined microstructure, MP35N offers unmatched performance and reliability.

Advanced Production and Quality Control

We meticulously produce our MP35N sheet using advanced manufacturing processes and strict quality control measures.

- Refined Melting Process: Manufactured using vacuum induction melting (VIM) and consumable vacuum arc re-melting (VAR).

- Precise Composition: Composed of 35% Ni, 35% Co, 20% Cr, and 10% Mo for optimal performance.

- Customizable Properties: We can tailor hardness from Rockwell C7 in the annealed state up to Rockwell C50 when cold worked and aged.

Our robust, vertically integrated supply chain allows us to manufacture high-performance refractory metals with the utmost quality, often exceeding customer expectations.

Your Partner for MP35N Sheet Products

At Elmet Technologies, we specialize in precision-engineering MP35N products using our state-of-the-art rolling services. Our team of engineers work closely with you to develop custom MP35N sheet solutions tailored to your unique requirements. Contact us today to learn more about how our dedication to quality, innovation, and exceptional customer service can elevate your next project.