Foil Tension Rolling

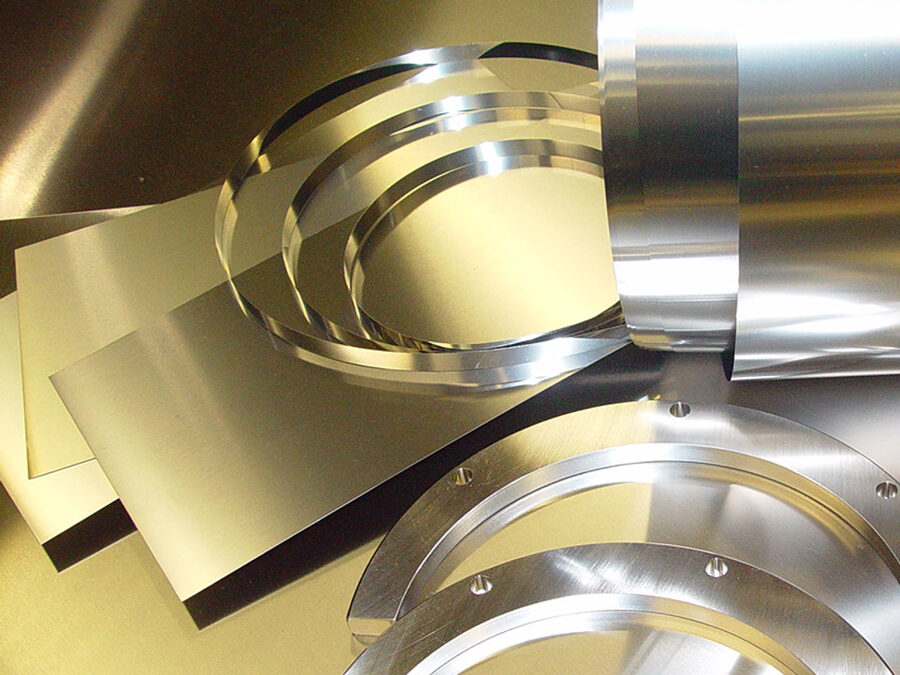

Elmet Technologies provides foil tension rolling services for a wide range of high-performance materials and refractory metals. With decades of metallurgical processing expertise, our team utilizes advanced rolling equipment to process metals to customer-specified and ultra-precise thickness, length, and surface finish. Typically, foil has a bright finish, free of surface defects or edge delamination, as determined by visual examination. Special mirror finish is available upon request.

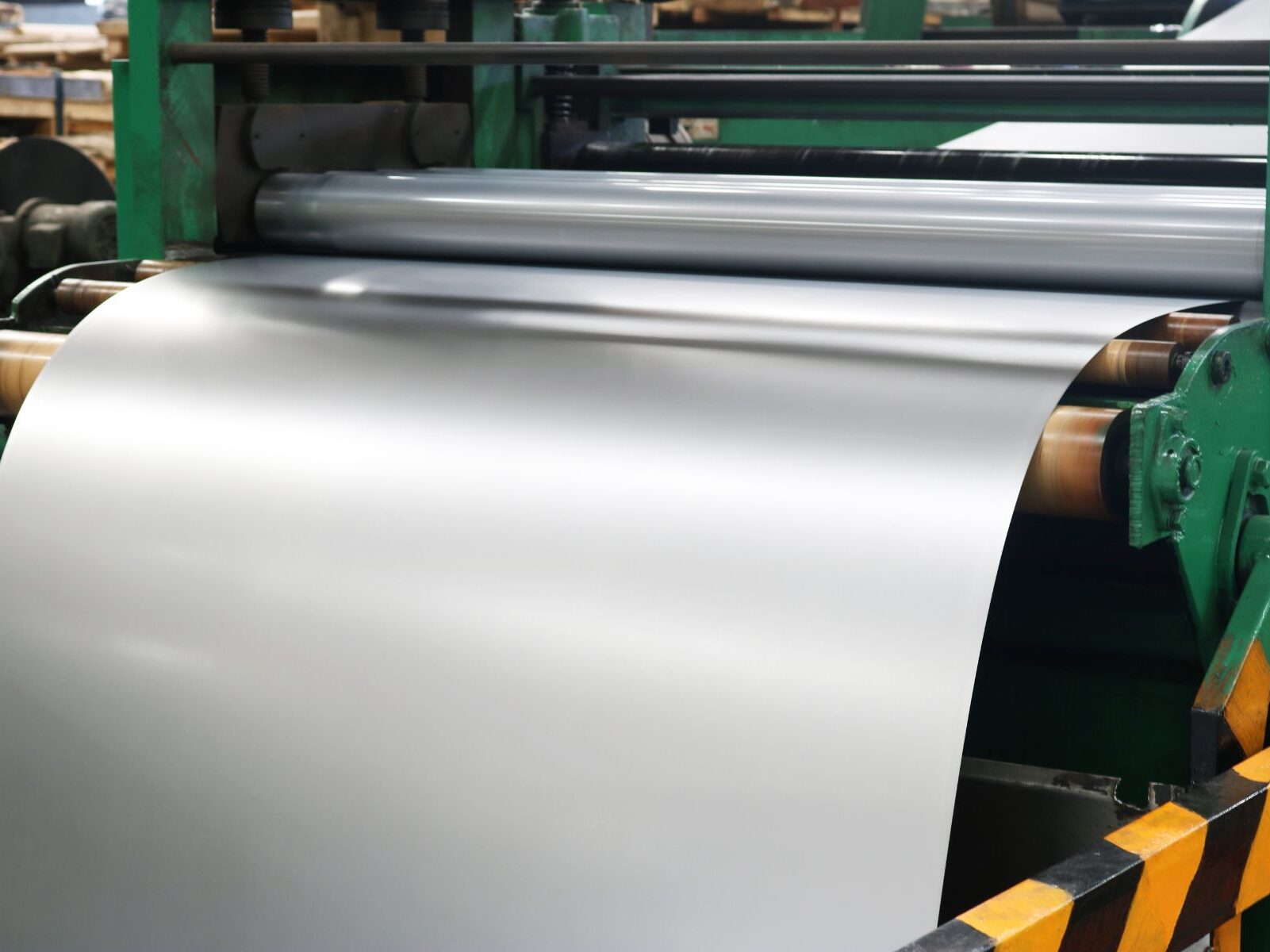

Foil tension rolling is a specialized industrial manufacturing process for production of thin foil, using controlled tension techniques during the rolling operation. These techniques support our foil products in meeting the stringent requirements of demanding applications in aerospace, defense, semiconductor, electronics, medical, and industrial processing. Elmet Technologies is committed to delivering high-quality products with superior material performance characteristics.

Precise Foil Tension Rolling Services

At Elmet Technologies, we specialize in precision foil tension rolling, offering expertly rolled high-performance metal products designed to meet your unique application requirements.

Our fully integrated manufacturing process and expertise in powder metallurgy enables us to assist in material processing for a wide range of high-performance metals.

Whether you require high-volume production or development of a prototype, the team at Elmet Technologies is here to assist in your rolling and material processing endeavors.

When you work with Elmet Technologies, you gain access to a team of dedicated experts committed to customer success, material performance, and manufacturing excellence.

High-Performance Molybdenum Alloys

Our foil tension rolling services produce high-quality molybdenum and molybdenum alloy foil in various thicknesses, lengths, and finishes. We leverage advanced rolling capabilities for foil less than 0.005 inches thick, making it ideal for a range of high-performance applications. With expertise in chemical etching for fine patterns, we support diverse markets with reliable foil rolling services.

Foil tension rolling with Tungsten

Elmet Technologies leverages its expertise with refractory metals to offer foil tension rolling services to assist in the production of thin material made of tungsten. Utilizing a series of advanced manufacturing techniques, we precisely tailor our foil to meet exact material and performance specifications. Our dedicated team of rolling experts works directly with customers to achieve optimal results for even the most demanding applications.

our advanced foil rolling capabilities

Leveraging the fully integrated manufacturing capabilities of our Euclid, Ohio facility, we offer extensive rolling capabilities for a wide variety of materials. Current capabilities include:

- Foil Rolling: several foil rolling mills for pure tungsten, pure molybdenum, molybdenum alloys, TZM, MoLa, MP35N, CuMoCu, NiMoNi, and a wide range of high-performance materials.

- Surface Conditioning: surfaces can be provided in a wide variety of options, including shiny, matte, satin, as-rolled finishes, or customer-specified, depending on the thickness and width.

- Heat Treatment: through rolling, annealing, and heat treating processes, Elmet Technologies can assist in creating the ideal condition for flat products based on the end application.

High-Performance Metal Rolling

Elmet Technologies is your partner in foil tension rolling and high-performance metal rolling services. Our advanced manufacturing capabilities allow us to quickly develop customer-specific solutions and process materials to meet your most unique project requirements.

With a customer-centric and quality-driven approach, we have the expertise and capacity to work alongside you on development projects as well as high-volume manufacturing.

We leverage 9 state-of-the-art rolling mills across our 3 United States facilities. Our equipment, combined with advanced powder metallurgy techniques gives us the unique ability to process materials and flat products specifically to the desired application.