Molybdenum Rolling

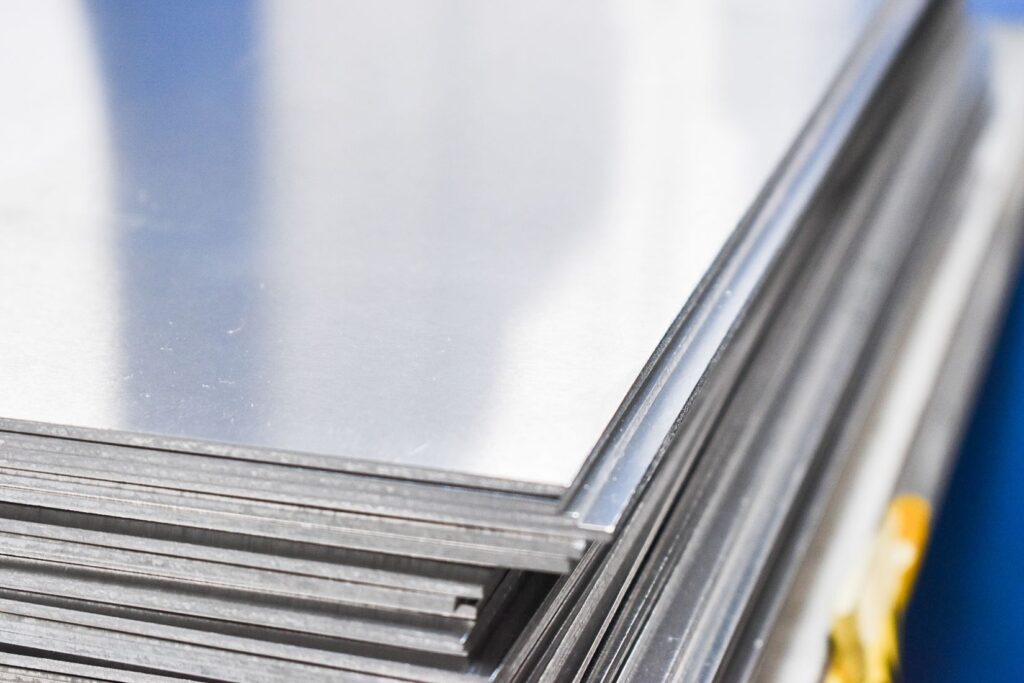

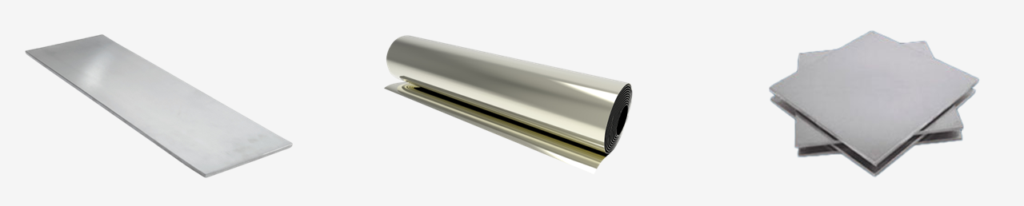

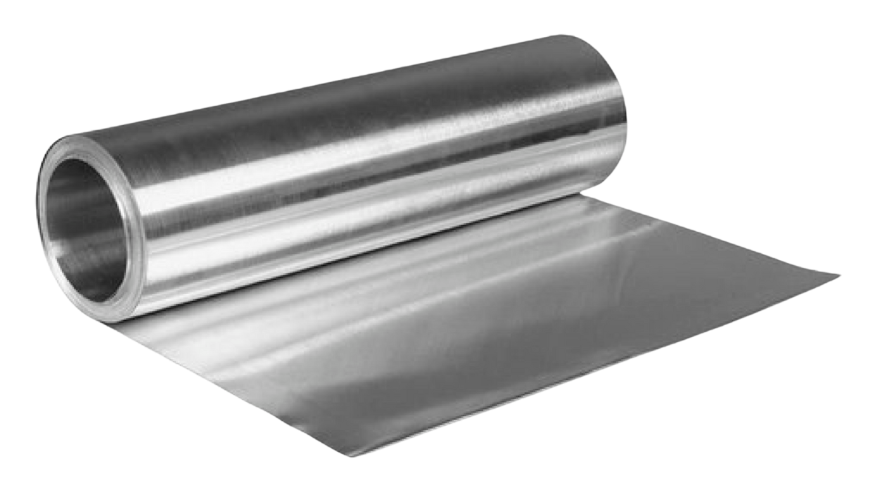

Elmet Technologies is a global leader in molybdenum rolling services, delivering exceptional expertise in material engineering and manufacturing. We transform high-purity refractory metals into precision-engineered products using advanced metal rolling techniques and state-of-the-art manufacturing technology. Through specialized rolling processes, we create custom forms of flat products, including plate, sheet, and foil, manufactured to meet the most demanding specifications.

Our meticulous control over material properties such as tensile strength, ductility, and grain size ensures superior performance across a wide range of applications. With decades of innovation and certified quality systems, Elmet Technologies sets the standard for excellence in molybdenum rolling services.

Advanced MOLYBDENUM rolling services

- Custom Solutions

- We offer a wide range of Mo forms and alloys, designed to meet the unique needs of your application.

- Unmatched Material Expertise

- With decades of experience in rolling refractory metals, we provide consistent quality and performance.

- Advanced Rolling Capabilities

- From custom sheet to precision foil, we deliver products tailored to your exact specifications.

- Certified Quality Systems

- Our certifications ensure high standards in manufacturing and quality control.

High-Quality Molybdenum products

Elmet Technologies provides various products and services to suit diverse application needs:

Molybdenum Alloys for Specialized Applications

- Copper Clad Molybdenum

- Combining copper’s conductivity with molybdenum’s strength, this material is ideal for high-performance applications requiring advanced thermal management.

- Titanium-Zirconium-Molybdenum

- Offers greater strength, higher recrystallization temperature, and improved creep resistance, perfect for demanding high-temperature environments.

- Lanthanated Molybdenum

- Combines molybdenum with lanthanum oxide for superior strength and thermal stability in extreme conditions.

- MP35N Alloy

- MP35N alloy offers ultra-high strength, plus corrosion resistance and other unique properties, making the material an ideal candidate for high-performance products.

Molybdenum: Hot Rolling and Cold Rolling

Elmet Technologies utilizes hot rolling and cold rolling processes to transform molybdenum into high-performance sheet, plate, foil, and flat products. The corrosion resistance of molybdenum ensures reliable performance in high-temperature environments and industrial processing.

Benefits of Molybdenum and Its Alloys

- Low Coefficient of Thermal Expansion

- Expands at a rate closely aligned with materials like glass and silicon, ensuring compatibility in high-performance applications.

- High-Temperature Strength

- With a melting point of 2620°C, it remains strong and stable in extreme environments, such as furnaces operating at 1600–2000°C.

- Thermal and Electrical Conductivity

- Excellent conductivity ensures reliable performance in applications requiring efficient energy transfer.

- Low Vapor Pressure

- Its low vapor pressure at high temperatures enhances its durability and precision in critical conditions.

- Corrosion Resistance

- Exceptional resistance to corrosion makes it ideal for harsh industrial environments, extending component lifespan and improving efficiency.

The Experts in Molybdenum Metal ROlling

Elmet Technologies is your trusted partner for high-quality molybdenum metal rolling. Whether you require custom rolling services, precision machining, or tailored material solutions, we have the expertise and capabilities to meet your requirements. Contact us today to discuss your next project.