MP35N Foil

Elmet Technologies is a leading manufacturer of MP35N foil with high-performance materials and products for a wide range of applications. Our MP35N alloy material is engineered for applications demanding ultra-high strength and exceptional corrosion resistance. From medical devices to aerospace components, our high-performance foil products are manufactured to exact customer specification. These products often meet or exceed the most demanding industry standards.

Made with a unique composition of 35% nickel, 35% cobalt, 20% chromium, and 10% molybdenum, MP35N is produced using advanced vacuum melting techniques to ensure high purity and performance. Our cold-rolled foil performs reliably in extreme conditions, withstanding temperatures from cryogenic levels up to 600°F. When strength, durability, and precision matter most, Elmet Technologies high-performance MP35N foil is the trusted choice for extreme environments.

High-Performance MP35N Foil

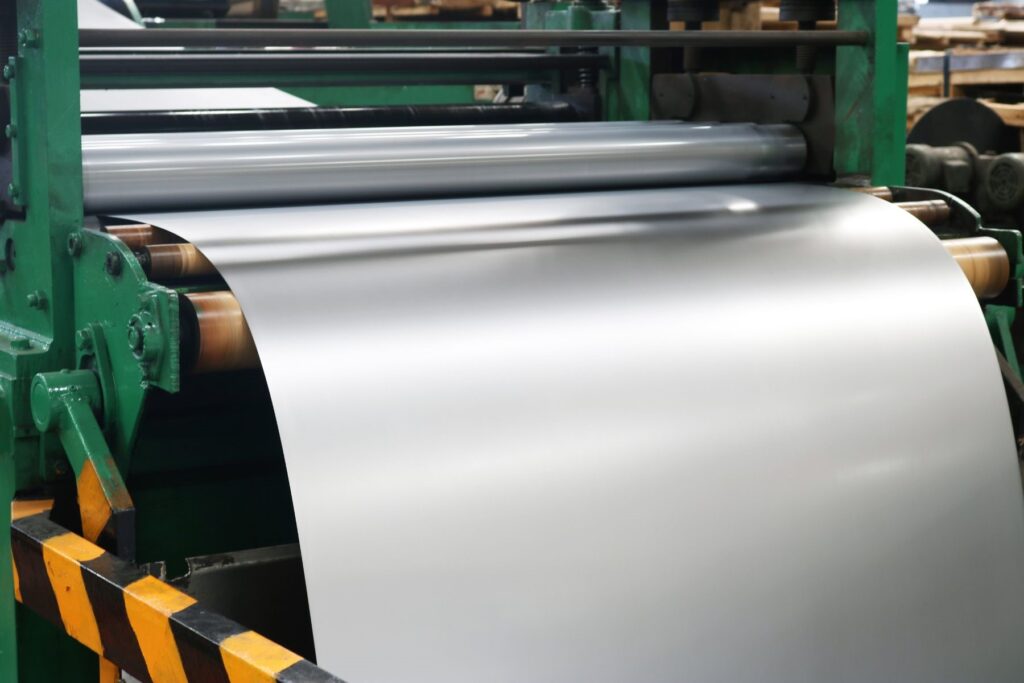

Elmet Technologies MP35N foil offers exceptional mechanical properties in a thin, versatile form. Our advanced cold rolling and aging processes maximize the material’s strength, ensuring reliable performance even under extreme stress.

- Exceptional Tensile Strength: Capable of achieving strength levels from 260 to 300 ksi (1790-2070 MPa).

- Maintains Toughness: Exhibits excellent ductility and toughness even at high strength levels.

- Temperature Performance: Functions reliably in extreme cold and at temperatures up to 600°F (316°C) without performance loss.

Precision-Engineered Foil for Superior Performance

We produce our MP35N foil using high-performance processes like vacuum induction melting (VIM) followed by vacuum arc re-melting (VAR) to ensure complete control over quality and consistency. We maintain a precise composition of 35% Ni, 35% Co, 20% Cr, and 10% Mo, and our cold-rolled foil is available in thicknesses from 0.002” to 0.0049” (0.0508mm to 0.124mm). Our robust, vertically integrated supply chain ensures superior foil products tailored to your specific requirements.

Key applications of MP35N Foil

The extraordinary properties of MP35N foil make it essential for specialized components where precision and reliability are critical.

- Medical: Ideal for intricate components requiring biocompatibility and high strength.

- Electronics: Used in demanding conditions where high performance is essential.

- Aerospace: Suited for lightweight components and other critical parts in aircraft and space applications.

- Research: Employed in advanced research projects where material performance is key.

Its versatility and durability make it an ideal choice across industries that demand the highest standards of performance.

Your Partner in Refractory Metal Solutions

At Elmet Technologies, we specialize in delivering high-quality MP35N foil solutions through precision engineering and advanced manufacturing techniques. Our engineers work closely with you to design custom solutions tailored to your unique application requirements. Contact the team at Elmet Technologies today to learn more about how our foil solutions can benefit your specific application.