Refractory Metal Rolling

Elmet Technologies provides industry-leading refractory metal rolling services and toll manufacturing for high-performance metals. Since 1929, we have proudly provided customers with innovative metal products and solutions, consistently meeting the rigorous demands of aerospace, defense, semiconductor, energy, industrial, and medical applications, Our materials are renowned for exceptional quality and performance, making them a trusted choice in critical applications.

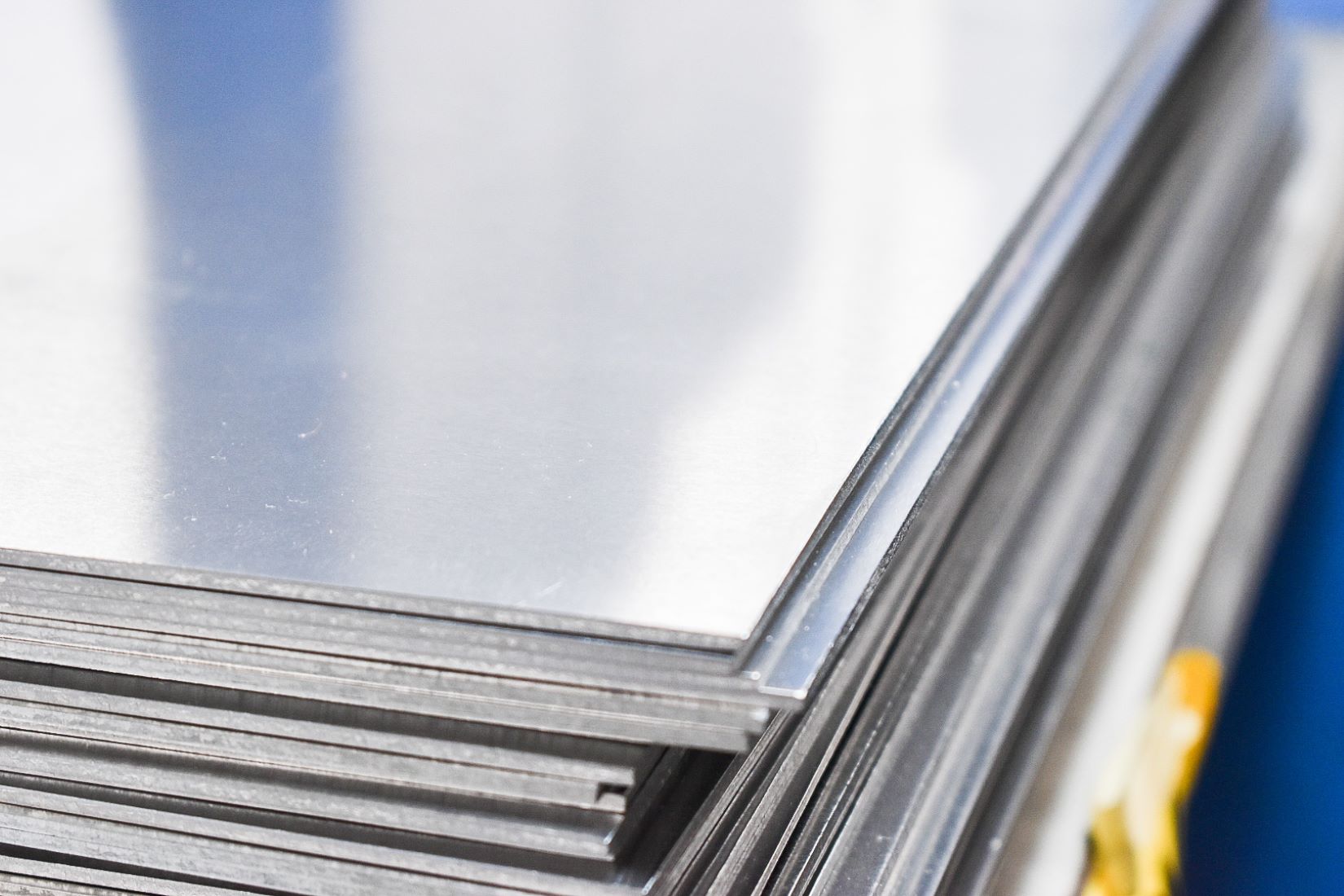

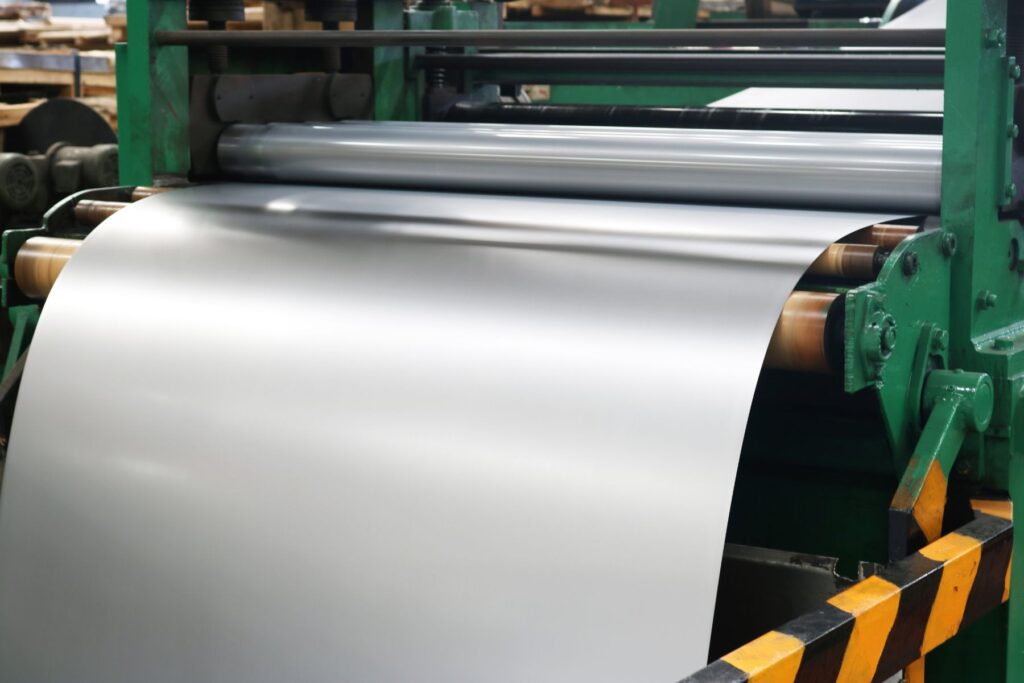

Our fully-integrated manufacturing process starts with high-purity metal powders, ensuring superior consistency and performance at every stage. Leveraging advanced powder metallurgy techniques, we produce plate, sheet, foil, and custom flat products with unparalleled precision and durability. Whether you require the rolling of refractory metals or specialty alloys, Elmet Technologies is your trusted partner for high-performance metal rolling and toll manufacturing services.

Refractory Metal Rolling: Our materials

Elmet Technologies specializes in metal rolling for a wide range of high-performance materials and specialty alloy systems, including:

- Tungsten (W): Known for its exceptional density, strength, and heat resistance. Our flat products (plate, sheet, and foil) are precision-engineered for extreme applications.

- Molybdenum (Mo): Offering superior tensile strength, ductility, and grain size control. Molybdenum flat products are ideal for high-temperature and industrial uses.

- Lanthanated Molybdenum (MoLa): With enhanced high-temperature performance and improved ductility, MoLa is ideal for aerospace, medical, and industrial applications.

- MP35N: A high-performance alloy with exceptional strength, corrosion resistance, and biocompatibility, MP35N is utilized in the aerospace, medical, and energy industries.

- Copper-Clad Molybdenum (CuMoCu): Engineered for superior thermal conductivity and electrical performance, CuMoCu is ideal for advanced electronics packaging.

- Nickel-Clad Molybdenum (Ni-Mo-Ni): Combining strength, thermal stability, and corrosion resistance, this advanced material system excels in extreme environments.

- TZM (Titanium-Zirconium-Molybdenum): Renowned for its high-temperature strength and thermal conductivity, TZM is utilized in several aerospace and industrial applications.

rolling and toll Manufacturing Services

We combine decades of expertise with cutting-edge manufacturing technology to deliver high-quality materials, products, and solutions for the most demanding applications.

- Hot and Cold Rolling: Precision rolling for a wide range of materials, including refractory metals, high-performance materials, and specialized alloy systems.

- Advanced Machining: Tailored metal solutions with options for custom machining and manufacturing to meet or exceed your application requirements.

- Extrusion and Rotary Forging: Toll manufacturing services for challenging and complex applications with extensive capabilities for large diameter metal processing.

- Specialized Metal Processing: Metal powder processing, consolidation and transformation, thermomechanical processing, additive manufacturing, and more.

extrusion and rotary forging: Material Capabilities

- Copper and Copper Alloys

- Stainless Steels

- 300 series | 400 series | 15-5 PH | 17-4 PH | Duplex

- Steel & XM19 Stainless Steel

- Tool Steels

- Nickel Base Alloys

- C276 | 400 | 600 | 625 | 690 | 718 | 800H | 925

- Monel & Inconel

- Titanium

- CP2 | 6AI | 4V

- Cobalt and Cobalt Super Alloys

- Aluminum

- Metal Matrix Composites

- Composite Billets

- Refractory Metals

The Experts in Refractory Metal Rolling

Elmet Technologies operates fully-integrated manufacturing facilities in Lewiston, Maine; Euclid, Ohio; and Coldwater, Michigan. Each location specializes in advanced refractory metal production. With capabilities that include extrusion, rotary forging, and metal rolling, we provide toll services to bridge production gaps and assist in metal processing. Our end-to-end manufacturing capabilities are supported our highly-skilled team of engineers and metallurgists to ensure exceptional quality and reliability. Discuss your refractory metal rolling and toll manufacturing requirements with us today.