Tungsten Rolling

Elmet Technologies provides tungsten rolling services for a wide range of pure and alloyed materials to support high-performance applications. We leverage decades of expertise in engineering and advanced manufacturing. Tungsten is known for its exceptional density, strength, and heat resistance. Elmet delivers high-performance solutions tailored to meet the demands of challenging applications across multiple industries, such as aerospace, defense, energy, and more.

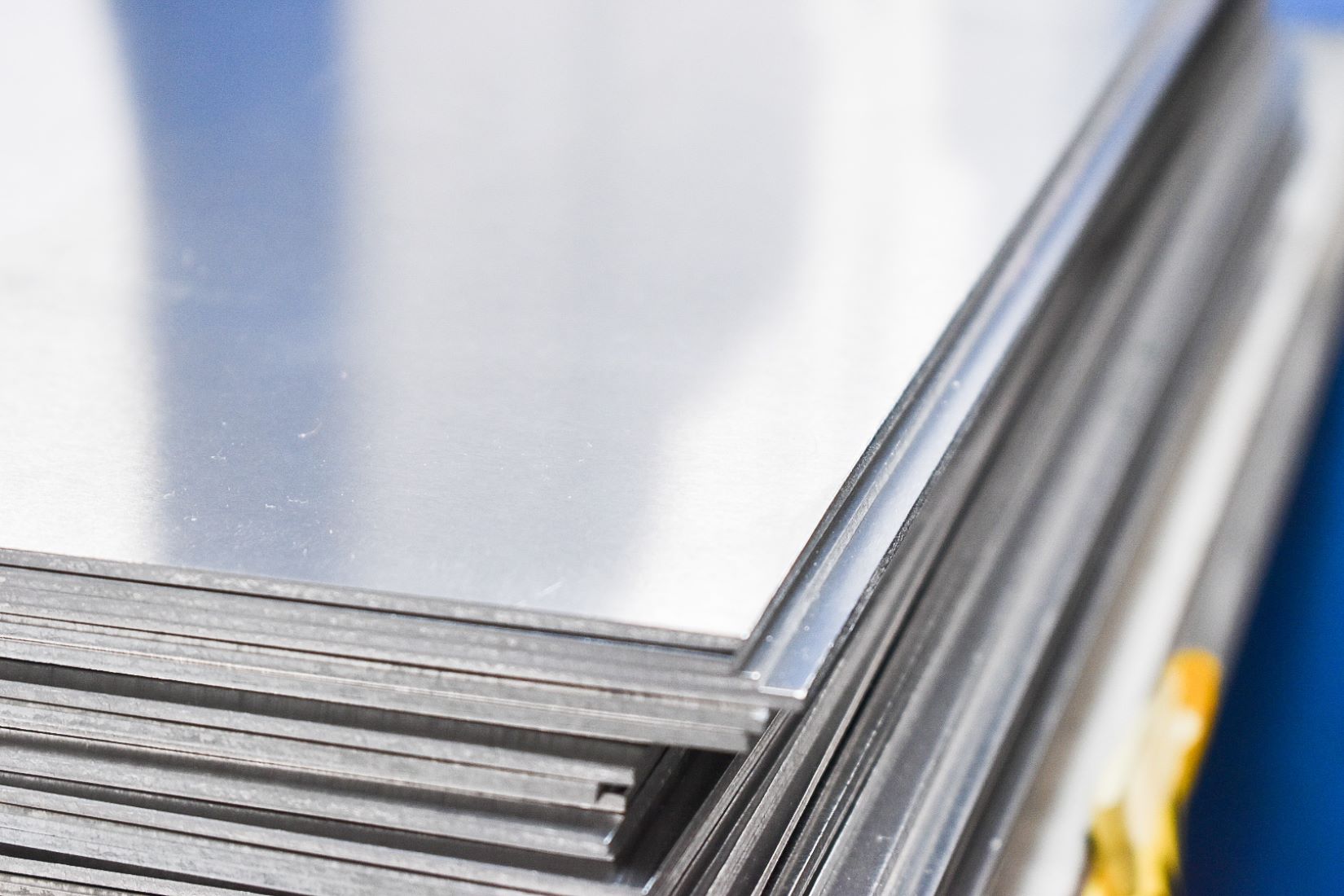

We utilize a fully integrated manufacturing process, beginning with high-purity tungsten metal powder to guarantee exceptional quality and consistency. Using advanced metal rolling techniques, we produce tungsten plate, sheet, and foil with both precision and versatility. These materials are offered as standalone mill products or can serve as inputs for our cutting-edge fabrication and machining services. Contact our dedicated toll services team to discuss your rolling needs.

Tungsten Rolling Capabilities

We operate 9 specialized rolling mills, optimized for tungsten and tungsten alloys, with exceptional dimensional accuracy and mechanical strength. Our capacity and flexibility allows us to produce various tungsten flat products that meet the most exacting performance and reliability standards. Our tungsten rolling capabilities include:

- Standard Mill Products: High-quality tungsten flat products (plate, sheet, and foil).

- Custom Rolling: Supporting prototype development and large-scale production.

Elmet Technologies works closely with its customers to fine-tune material properties like ductility, tensile strength, and hardness. We optimize every piece for its intended application, ensuring durability and reliability.

Tungsten Alloys for Specialized Applications

Elmet Technologies offers advanced tungsten alloys tailored to meet specific performance needs. Our lanthanum-doped tungsten (WLa) exhibits enhanced high-temperature performance, characterized by improved creep resistance and strength. Tungsten heavy alloys (WHA) offer exceptional density, ideal for applications such as radiation shielding, balance weights, and kinetic energy penetrators. Potassium-doped tungsten (WK) is engineered for high-temperature, non-sag uses in industries such as lighting and electronics, offering superior strength and machinability.

Custom Rolling Services for Critical Applications

Elmet Technologies utilizes advanced engineering and manufacturing techniques to deliver exceptional tungsten rolling services for critical applications. With nearly a century of experience in refractory metal manufacturing, we combine advanced technologies and proven expertise to produce tungsten materials with high-performance characteristics.

- Plate: Available in standard and custom thicknesses.

- Foil: Available in a wide variety of dimensions.

- Sheet: Cold rolling a wide range of sheet products in various thicknesses.

- Custom Flat Products: Hot and cold rolling to meet customer specifications.

Tungsten: Rolling for Strength and stability

- Highest Melting Point: Withstands extreme temperatures up to 3420°C.

- Exceptional Density: At 19.25 g/cm³, tungsten is one of the densest elements, offering unmatched durability.

- Corrosion Resistance: Maintains resilience against chemical wear in harsh environments.

- Low Thermal Expansion: Ensures stability under extreme conditions.

- High Elastic Modulus: Delivers superior stiffness and strength under pressure.

your Partner in Tungsten Rolling Services

With nearly a century of refractory metals expertise, Elmet Technologies is a trusted partner in advanced metal rolling services and flat products for demanding applications. Operating from our fully integrated, U.S.-based facilities, we use state-of-the-art equipment to roll, process, and refine tungsten materials to the most precise specifications.

Elmet Technologies sets the standard for performance and reliability in tungsten rolling solutions with its plate, sheet, foil, and custom flat products, services, and capabilities.